Back to the Future

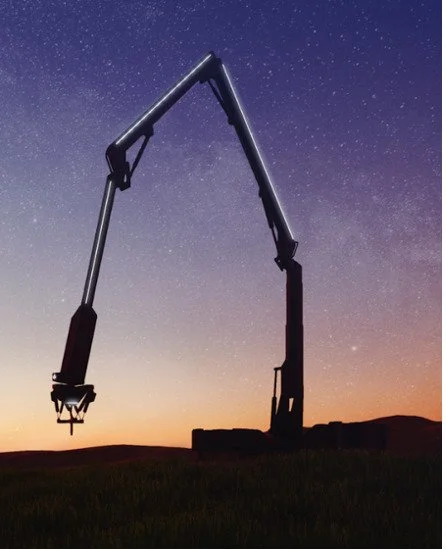

Image courtesy of iconbuild.com

Back to the Future

by Sweiskloss

May 22, 2025

by Sweiskloss

May 22, 2025

Photo courtesy of Iconbuild.com

BioHome,3D, Photo courtesy of composites.unmaine.edu

Image courtesy of Azure Printed Homes.com

House Zero, photo courtesy of iconbuild.com